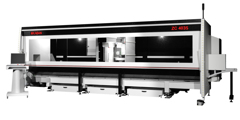

- Average axis speeds exceeding 100 m/min

- Profile processing length: 6500 mm

- Double-station profile processing length: 3000 mm x 2

- Machinable cross-section size: 650 x 350 mm

- Number of vices: 8

- Spindle motor: 10-12 kW, 24,000 rpm

- Number of tool magazines: 16

- Ø 500 mm saw blade

- Mitsubishi CNC control unit

- Automatic tool length measurement

- Automatic positioning vices

- Automatic tool recovery in case of power failure

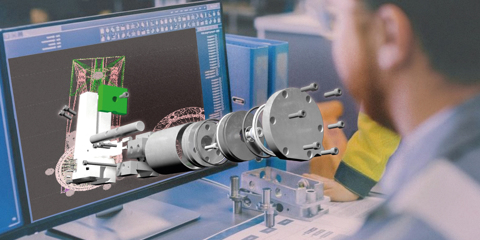

Design

- With the profile fixed; performs all similar operations such as milling, notching, drilling, threading, countersinking and cutting.

- With its axis speeds of 100 m/min on average, it processes much faster than equivalent products.

Control Panel

- 19'' screen

- Windows-based, user-friendly Kaban interface with easily adjustable parametric structure

- Compatibility with .NCX extension software

- High performance 4+1 axis Mitsubishi CNC control unit

- Optical communication and command boost

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

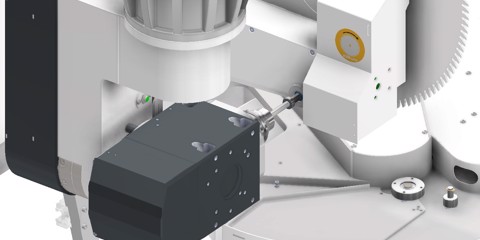

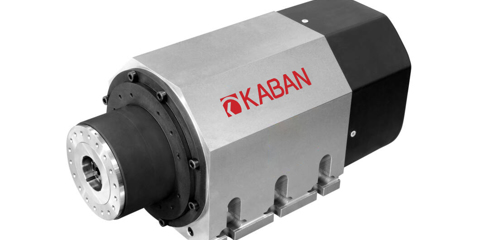

Spindle

kW max. 24,000 rpm.

- Tool cooling system with oil-air mixture spraying, speed adjustment and liquid level sensor.

Magazine

- When moving from one process to another, time is saved thanks to the automatic tool change feature.

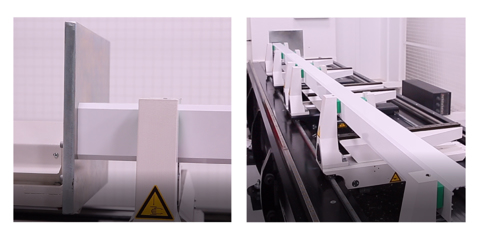

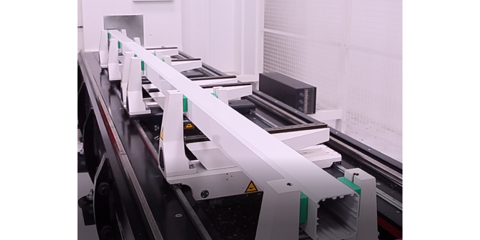

Profile Supports

- Suitable for working with long profiles

Vices

- In accordance with the ergonomics of use, the fact that the clamps constants are in the front part and the roller system provides convenience to the operator when loading and unloading the profile.

- There are clamps that can be automatically moved according to the order of operation.

- It keeps the profiles at the desired tightness thanks to 3 different pressure tightnesses that can be defined on the profile according to the profile thickness.

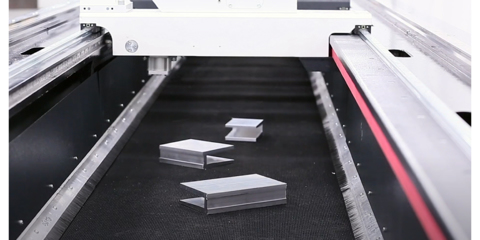

Chip Conveyor

Safety

- Auto-recovery function that sends the spindle to the safe zone

- Operational safety with protective fences and safety barriers

|

Description

|

|||||||

| Machine Features | X Axis | Motor Power | 3,5 | kW | |||

| X Axis | Axis Speed | 140 | m/d | ||||

| X Axis | Part Processing Length | 6500 | mm | ||||

| Y Axis | Motor power | 1,5 | kW | ||||

| Y Axis | Axis Speed | 120 | m/d | ||||

| Y Axis | Part Machining Width | 650 | mm | ||||

| Z Axis | Motor power | 1 | kW | ||||

| Z Axis | Axis Speed | 40 | m/d | ||||

| Z Axis | Machining Height | 350 | mm | ||||

| A Axis | Motor power | 0,75 | kW | ||||

| A Axis | Axis Speed | 146 | º/sec | ||||

| A Axis | Angle | ±110 | º | ||||

| C Axis | Motor power | 0,75 | kW | ||||

| C Axis | Axis Speed | 146 | º/sec | ||||

| C Axis | Angle | ±180 | º | ||||

| Spindle | Motor power | 10-12 | kW | ||||

| Spindle | Maximum Rotation Speed | 24000 | d/d | ||||

| Tool magazine | Number of Tools | 16 | Piece | ||||

| Tool magazine | Saw Maximum Diameter | 200 | mm | ||||

| Saw | Diameter | 500 | mm | ||||

| Clamp | Axis Speed | 20 | m/d | ||||

| Clamp | Number of Vises | 8 | Piece | ||||

| Technical Specifications | Weather | Pressure | 6-8 | Bar | |||

| Weather | Total Air Consumption | 350 | l/d | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Strength | 24 | kW | ||||

| Weight | Net | 13115 | kg | ||||

| Weight | Gross | 13300 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 11330 | mm | ||||

| Machine Dimensions | Width | 4250 | mm | ||||

| Machine Dimensions | Height | 2903 | mm | ||||