- Lame Sash Cleaning

- High-Speed, Maximum-Quality Operation

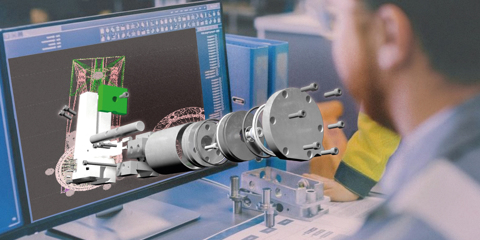

Design

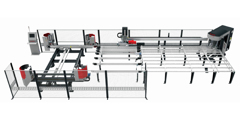

- It is designed for welding and cleaning four corners of PVC profiles at the same time.

- Practical mold replacement system.

- The brush system prevents the deterioration of the surface quality during the transition.

Control Panel

- Automatic profile recognition and tolerance system ensures the continuity of standard production.

- Profile recognition information is automatically transferred from the welding machine.

- Special software which enables the

selection of profile trolley stocking arrangment from the screen in order to make customer based production.

- Parameter settings are made easily.

- Linear measurement system provides measuring stability.

- Information transfer with SD card.

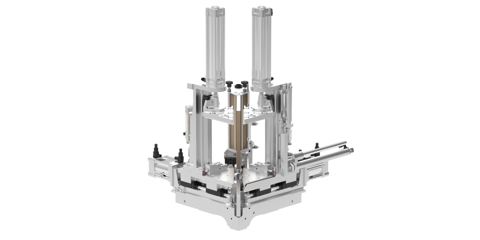

Welding Unit

- PID system to adjust heating degree and time parameters independently.

- Saving of time and cost thanks to roller formed teflon replacement system.

- Long lasting heating plate distributes the heat homogeneously.

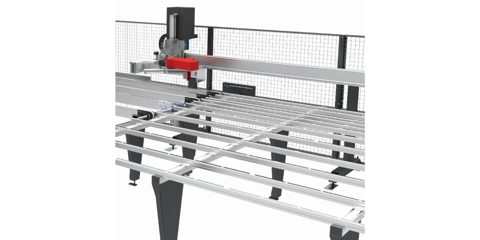

Transfer Systems

- The frames are transfered to the pickup point of the robot, where it waits to cool the frames and increase the welding quality.

- After cooling down, it takes the frames to the CNC corner cleaning machine.

- Robot technology brings the frames to their proper positions for each corner of the frames to be cleaned respectively.

- Corner positioning is performed by rotating small frames by 1 sec, large frames by 1.5 - 4 sec.

- Decouples the ratio between the small frame and the large frame and optimizes the rotation speed.

- The rotating unit performs the second operation while cleaning the corner.

- The conveyor system makes the transfer of frames between units fast and decoherent.

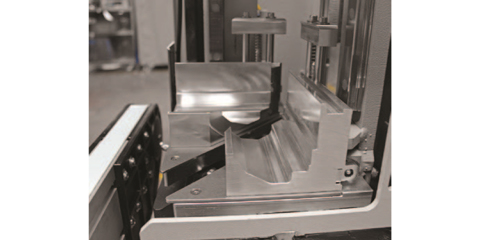

Cleaning

- Cleans the top and bottom of laminated and white profiles with different blades with superior quality.

- When the corner cleaning machine is used alone, it cleans a corner in at least 9-18 seconds according to the type of profile.

- Thanks to its special program, it performs automatic identification and cleans all corners without operator intervention

- Cleans corners in superior performance with 12pcs tools.

- It can be cleaned with the existing machine without using additional tools.

- After the first corner is cleaned, it turns the frame to clean all the corners respectively.

- The cleaning time of 4 corners is on average 50 seconds depending on the frame size.

- Due to the location of the corner cleaning machine, it provides ease of automatic and manual operation.

- It can also be welded by entering a manual measurement without using a barcode reader.

- Automatically cleans frames with a servo-controlled lame sash unit.

- It can clean the inner parts of the renovation frames.

- The robot and CNC corner cleaning machine can work without welding machine or with any other welding machine.

|

Description

|

|||||||

| Welding Measures | Profile | Height | 210 | mm | |||

| Profile | Width | 130 | mm | ||||

| Width / Length | Maximum | 2460 / 3575 | mm | ||||

| Width / Length | Minimum | 325 / 410 | mm | ||||

| Angle | Welding | 90 | ° | ||||

| Welding Machine Axes | X Axis | Motor power | 0,75 | kW | |||

| Y Axis | Motor power | 2 x 0,4 | kW | ||||

| Conveyor | Motor power | 2 x 0,37 | kW | ||||

| Cooling Unit | Conveyor | Motor power | 0,55 | kW | |||

| Conveying and Turning Unit | X Axis | Motor power | 1,5 | kW | |||

| Y Axis | Motor power | 0,75 | kW | ||||

| Corner Cleaning | X Axis | Motor power | 0,75 | kW | |||

| Y Axis | Motor power | 0,4 | kW | ||||

| Z Axis | Motor power | 0,75 | kW | ||||

| Saw | Motor power | 1,5 | kW | ||||

| Saw | Rotation Speed | 12000 | rpm | ||||

| Saw | Diameter | 250 | mm | ||||

| Milling | Motor power | 2 x 0,55 | kW | ||||

| Milling | Rotation Speed | 18000 | d/d | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 180 | l/d | ||||

| Feed | Voltage | 230 (Köşe Tem.) /400 (Kaynak) | V | ||||

| Feed | Power | 17,8 | kW | ||||

| Weight | Net | 4060 | kg | ||||

| Weight | Gross | 4835 | kg | ||||

| Sound | Level | 96 | dB | ||||

| Machine Dimensions | Length | 14279 | mm | ||||

| Machine Dimensions | Width | 5940 | mm | ||||

| Machine Dimensions | Height | 2154 | mm | ||||